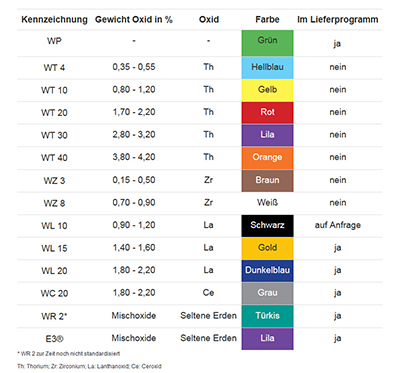

Colour codes for tungsten electrodes

| Identification code | Weight of oxide in % | Oxide | Colour | In the range |

| WP | - | - | Green | |

| WT 4 | 0.35 - 0.55 | Th | Light blue | No |

| WT 10 | 0.80 - 1.20 | Th | Yellow | No |

| WT 20 | 1.70 - 2.20 | Th | Red | No |

| WT 30 | 2.80 - 3.20 | Th | Purple | No |

| WT 40 | 3.80 - 4.20 | Th | Orange | No |

| WZ 3 | 0.15 - 0.50 | Zr | Brown | No |

| WZ 8 | 0.70 - 0.90 | Zr | White | No |

| WL 10 | 0.90 - 1.20 | La | Black | On request |

| WL 15 | 1.40 - 1.60 | La | Gold | |

| WL 20 | 1.80 - 2.20 | La | Dark blue | |

| WC 20 | 1.80 - 2.20 | Ce | Grey | |

| WR 2* | Mixed oxides | Noble metals | Turquoise | |

| E3® | Mixed oxides | Noble metals | Purple |

*WR 2 not yet standardised

Th: Thorium; Zr: Zirconium; La: Lanthanum oxide; Ce: Ceroxide

WP electrodes:

- Pure tungsten electrodes

- AC welding of aluminium alloys

- Not suitable for DC welding

WT electrodes:

- Slightly radioactive due to addition of thorium

- Refrain from using due to increased health risks

- Improved ignition characteristics and better current carrying capacity compared to WP electrodes

WZ electrodes:

- Lower risk of contamination of weld thanks to addition of zirconium

- Tungsten electrodes for AC welding of aluminium alloys

- Only limited suitability for DC welding

WL electrodes:

- Increased ignitability thanks to lanthanum oxide

- Suitable for DC and AC welding

- Can be used for unalloyed and high-alloy steels; aluminium, titanium, nickel, copper and magnesium alloys; and for microplasma welding

- Ideal for use in low current range

- Good substitute for WT electrodes

WC electrodes:

- Very good ignition and reignition characteristics thanks to ceroxide

- Suitable for DC and AC welding

- Can be used for unalloyed and high-alloy steels and aluminium, titanium, nickel, copper and magnesium alloys in the lower and mid current range

- Good substitute for WT electrodes

WS electrodes:

- Variable, non-standardised composition

- Suitable for DC and AC welding

- Can be used for unalloyed and high-alloy steels and aluminium, titanium, nickel, copper and magnesium alloys in the lower and mid current range

- Long service life and very durable