Due to rising wage costs and the increasing pressure from competition internationally, more and more companies are having to streamline their production processes – something that also applies to welding. To allow users from industry, production, education and trade to manufacture at a faster rate but also to a consistently high standard of quality, EWM GmbH offers a complete welding service specifically customised to individual needs. This includes collaborating robots, as well as turnkey and compact robot cells and robot systems with partly or fully automatic offline programming. As a welding technology manufacturer, we take advantage of the current possibilities of Industry 4.0. This way, both small and large series can be produced flexibly, reliably and economically.

One of the key requirements in welding production is consistently high and reproducible product quality – both for welding large series and small series, and even right down to just single batches. As a complete provider of arc welding technology, we are focusing more and more on software solutions that create offline robotic welding programmes, based around 3D CAD design data. Thanks to its modular concept, the software can be expanded as required, from partly automated through to fully automated offline welding robot programming. This way, users can make production much more effective, even for small series, and they can reduce online programming time by up to 95%. As a result, the time used previously for teaching and programming can be used as production time – the robot doesn’t stop.

A huge range of solutions

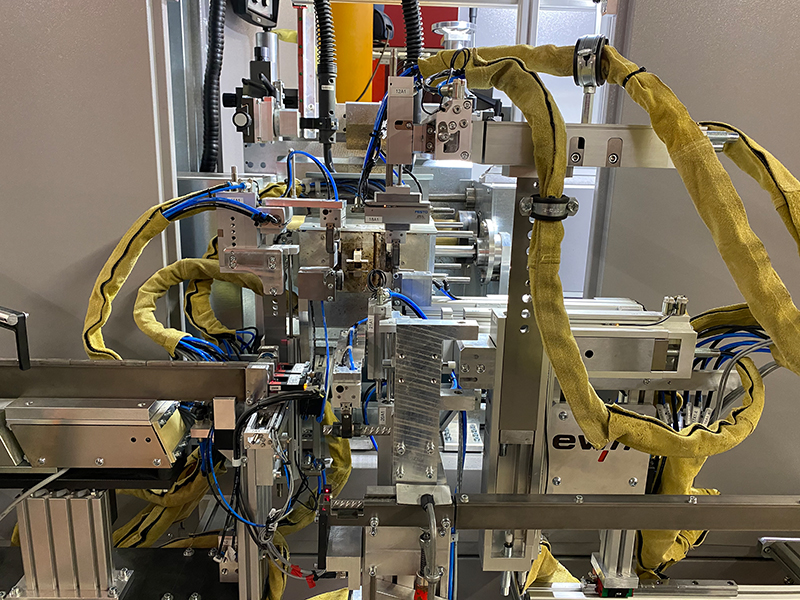

EWM GmbH offers a particularly large range of complete solutions for automation in welding production. The intelligent software for offline robot programming is used both in compact robot cells and customised complete systems from the modular EWM complete solutions. Our compact and standardised robot cells are delivered pre-assembled and ready-to-weld, and come with a base plate and casing. They can also be transported using a forklift or lorry and quickly commissioned. Furthermore, we provide an extensive range of individual, turnkey complete systems from our modular solutions. With our collaborating robots, we have designed an intuitive, controllable entry-level solution for welding automation with no programming knowledge necessary. Co-bots can be programmed quickly, flexibly and simply. Users are therefore best prepared for welding simple tasks with a consistently high standard of quality, even with small batches as is often required in manufacturing, for example.