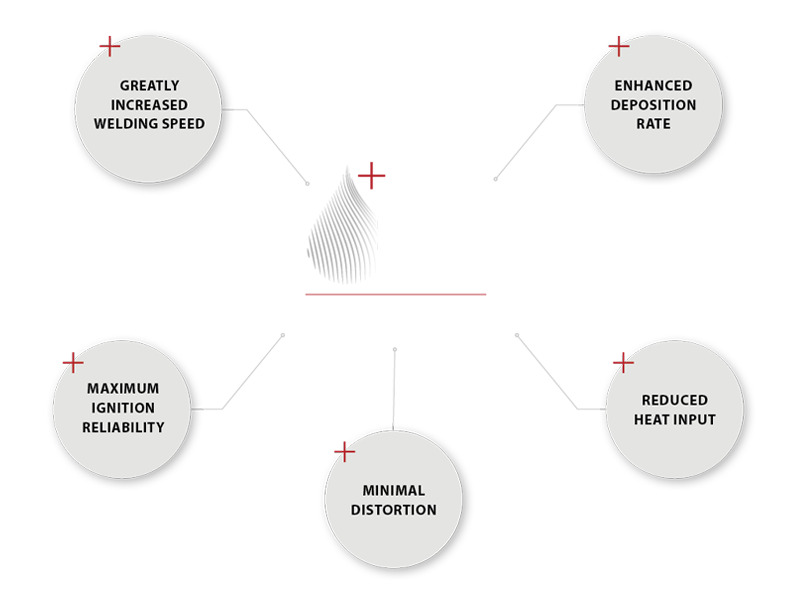

Greatly increased welding speed

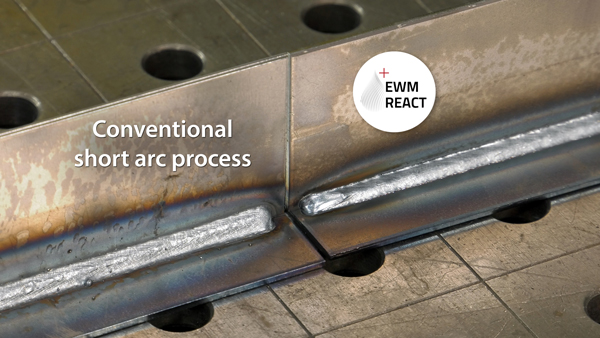

The Titan XQ R is our most high-performance power source for automated welding and makes EWM React our most stable and efficient welding process. With EWM React, you can weld more than 100% faster than with other processes. What that means for you: you achieve your desired results faster – and their quality is significantly higher and more reproducible.

Enhanced deposition rate

The deposition rate with EWM React is twice as high compared to the standard short arc. The reason for this is the active movement of the wire. Pushing it towards the weld pool in a rapid rhythm and then pulling it back again significantly increases the range of the short arc. In some cases, the deposition rate is even in the range of the spray arc.

Maximum ignition reliability

The extremely high stability of the arc and the precise wire movement result in maximum ignition reliability. This makes EWM React a welding process that produces high-quality weld seams in the shortest possible time. The extremely high ignition reliability also lets you better control the process and reduces any reworking that may be required.

Minimal distortion

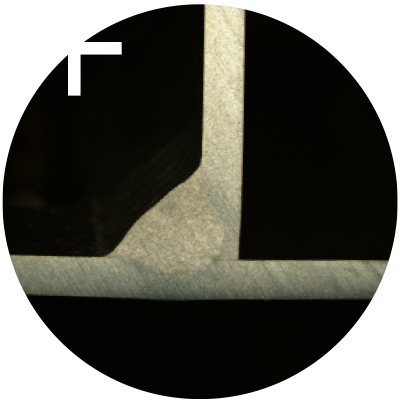

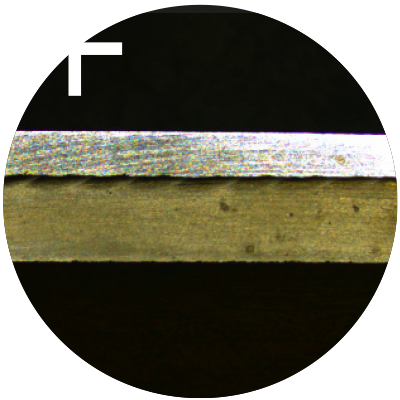

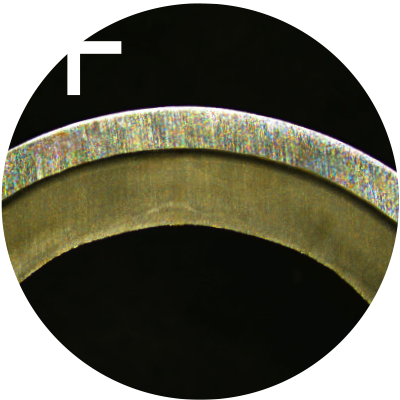

One of the biggest advantages of EWM React is particularly evident when welding CrNi components and processing thin material thicknesses: low distortion. It results from the fact that the RCC module produces a very low-energy short arc. This lowers the energy per unit length and the heat input, and significantly reduces distortion.

Reduced heat input

The numbers speak for themselves. Compared to the standard short arc, the deposition rate is twice as high – with a simultaneous reduction in heat input of up to 35%. Because the range of the short arc is significantly extended by the active wire movement, reduced heat input is possible despite high welding speeds and an increased deposition rate. This is precisely why EWM React is suitable for processing many different materials.

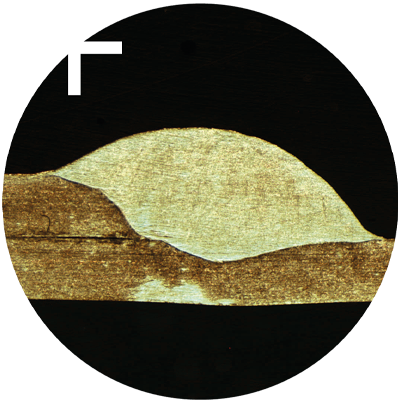

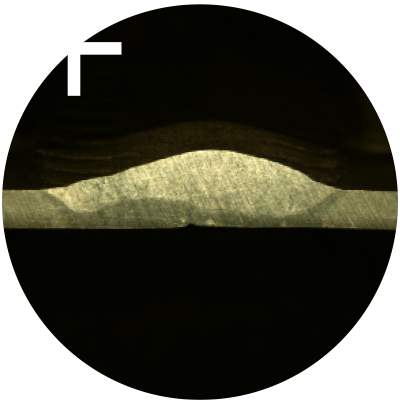

Full control over droplet transfer

EWM React delivers what you want in a precise and stable automation welding process. With this welding process, we give you full control over droplet transfer. Instead of falling off the electrode, the droplet passes safely into the weld pool despite high welding speeds. This results in perfect weld seams which you can rely on even under the heaviest loads. We utilise the high deposition rates of the spray arc range and combine them with all the advantages of the short arc. Just as low spatter as the pulsed arc, but cooler in every power range. Speed isn’t everything, though – we take productivity to a new level for you.

Weld more than

100%

faster

30%

less

welding fumes

Almost 0%

spatter

compared to

short arc

Gap bridging

up to 2 mm

35%

less

heat input

Extremely

stable

ignition and

welding process

2 x

higher deposition rate

compared to standard short arc

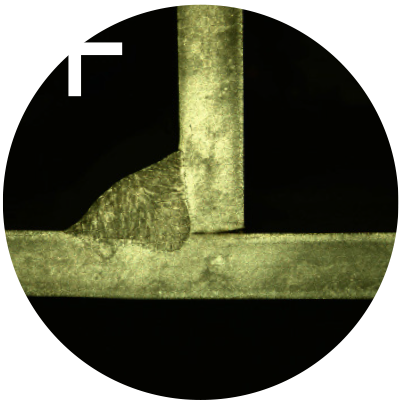

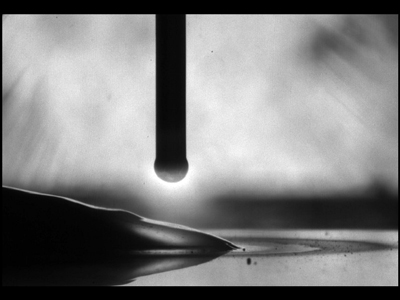

The wire is actively moved toward the weld pool at high speed. The arc ignites on the molten metal and produces a molten droplet at the same time.

At the moment when the wire comes into contact with the molten metal, the molten droplet in the short circuit is transferred to the weld pool. The RCC module controls the short-circuit resolution.

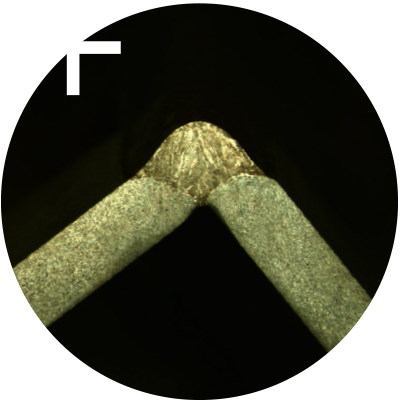

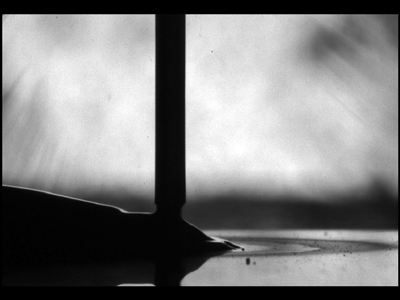

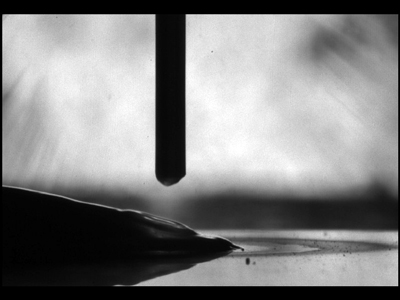

As a result of the active backward movement, the wire is drawn from the weld pool with high precision and the arc reignites.

As a result of the active mechanical backward movement, the wire is drawn from the weld pool with high precision and the arc reignites.

The combination of the quick current reduction offered by the RCC module and the controlled mechanical wire movement allows spatter-free results with unbeatable process stability.

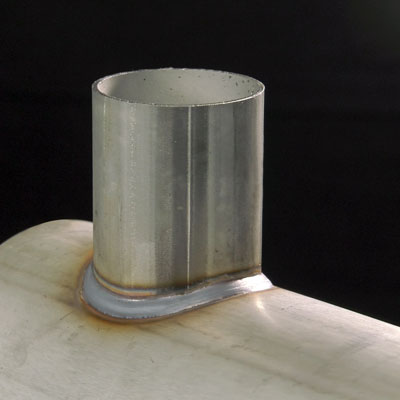

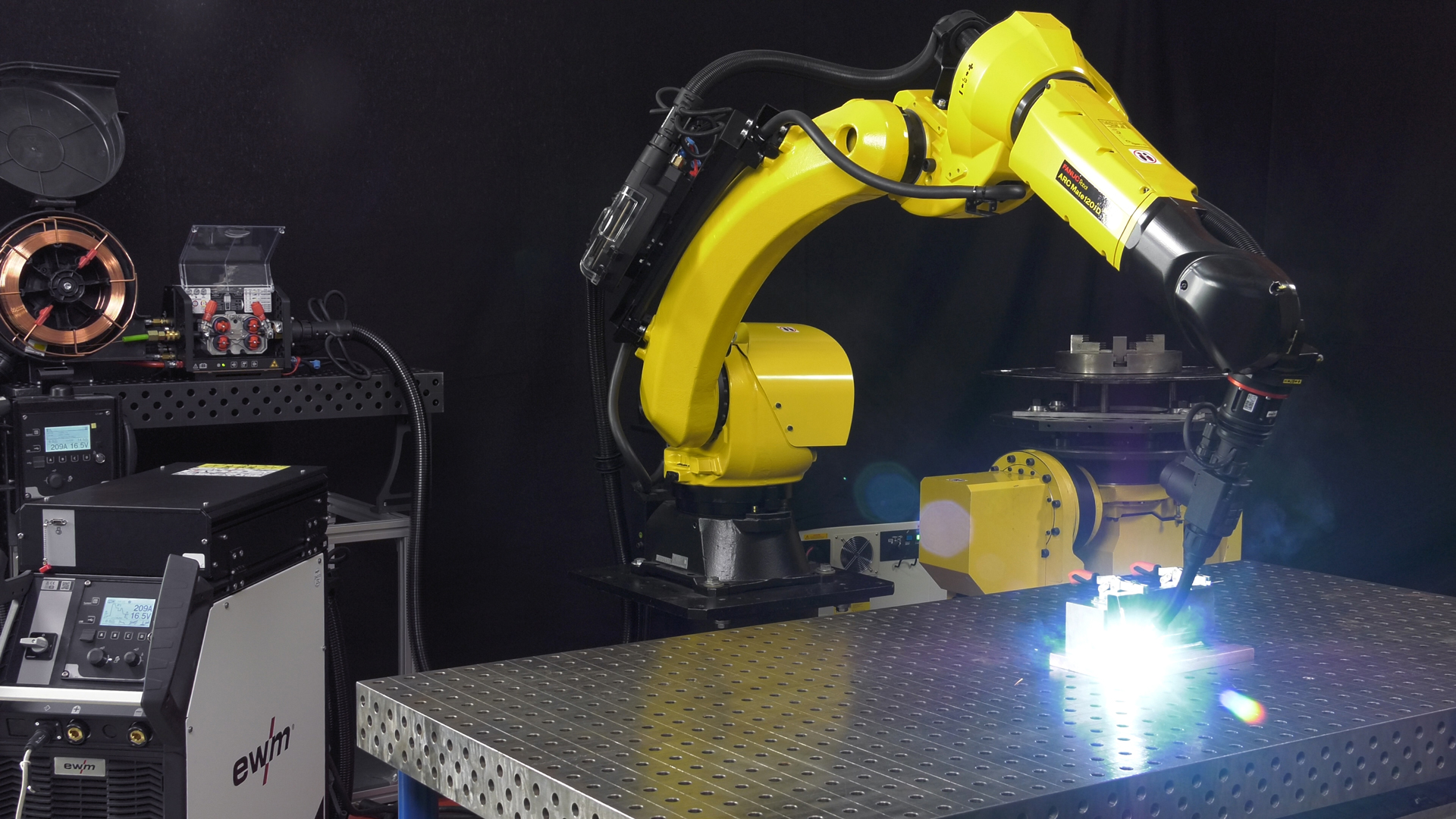

The power source

The individual components are optimally matched to each other and form a perfect team. The basis for the resulting weld seams is our power source: the

Titan XQ R with integrated RCC module and EWM React licence.

The wire feeder

Interference-free and reliable, our

M Drive 4 Rob 5 (with option PP) wire feeder ensures a constant wire supply via a matched average value.

The wire buffer

The wire buffer is inserted between the wire feeder and the robot torch. It acts as a link between the individual components to compensate for the active wire movement.

The robot welding torch

Our automation experts have developed a robot welding torch with a highly dynamic motor specifically for EWM React. It is the driving force behind the reversing wire movement. It pushes the wire towards the workpiece at a rapid rhythm and actively pulls it back again. You already know our torch necks for all applications – they are also ideal for EWM React.

EWM is your full-service provider

You already expect a lot from our automated welding technology, but can expect even more from our entire automation team. Show us your problem – we have the right solution for you in our repertoire. And if not? Then we develop one! This is exactly how EWM React was created – from the challenges of our customers. This is how we constantly add more and more services to our range and continually improve our tools.

Because: We are welding. We are welding, and you get only the best from us.

You would like more information or have a specific enquiry?

Then we should talk. Send us a message!